Are you a hobbyist looking to create your own DIY PCB testing tools or homemade PCB measurement equipment? Building custom testing tools can save money, enhance your skills, and give you tailored solutions for troubleshooting circuits. In this guide, we’ll walk you through simple PCB testing circuits, offer tips on PCB testing for hobbyists, and share basic PCB troubleshooting techniques to help you design and build effective tools at home. Whether you’re debugging a circuit or measuring signals, this blog will provide practical, step-by-step advice to get you started.

Why Build Your Own PCB Testing Tools?

For hobbyists, having the right tools to test and measure circuits is essential. Commercial equipment like multimeters and oscilloscopes can be expensive, especially for those just starting out. By building your own DIY PCB testing tools, you gain several advantages:

- Cost-Effective: Homemade tools often cost a fraction of store-bought alternatives.

- Customizable: Tailor your equipment to specific needs, like testing a particular voltage range or signal frequency.

- Learning Experience: Designing and assembling your tools teaches you about electronics and circuit design.

In the sections below, we’ll explore beginner-friendly projects for homemade PCB measurement equipment and provide actionable steps to build them.

Getting Started with PCB Testing for Hobbyists

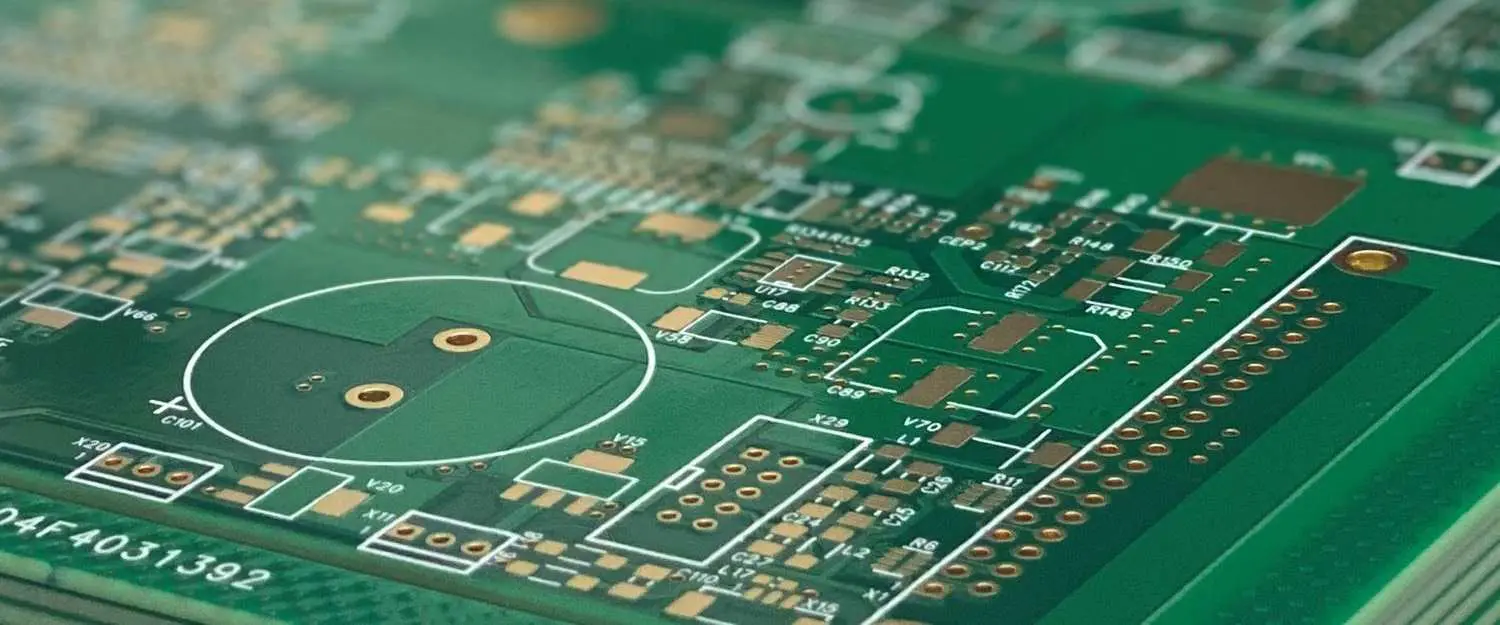

Before diving into specific projects, let’s cover the basics of PCB testing for hobbyists. Testing a printed circuit board (PCB) involves checking for issues like short circuits, open connections, or incorrect component values. As a hobbyist, you don’t need advanced gear to get started. Here are the fundamental steps and tools you’ll need:

- Basic Tools: A multimeter for measuring voltage, current, and resistance; a soldering iron for assembly; and a breadboard for prototyping.

- Knowledge of Circuits: Understand basic concepts like continuity, impedance (often measured in ohms, e.g., 50 ohms for many RF circuits), and signal behavior.

- Safety First: Always work with low voltages (under 12V is ideal for beginners) to avoid shocks or damage.

With these basics in mind, let’s move on to building simple PCB testing circuits that can help you troubleshoot and measure effectively.

Project 1: Building a Simple Continuity Tester

A continuity tester is one of the most simple PCB testing circuits you can build. It helps detect breaks or shorts in a circuit by producing a sound or light when a connection is complete. This is a great tool for basic PCB troubleshooting techniques.

Materials Needed

- 9V battery and connector

- Buzzer or LED (with a 220-ohm resistor if using an LED)

- Two test probes (can be made from insulated wires with exposed tips)

- Small PCB or perfboard

- Soldering iron and solder

Steps to Build

- Design the Circuit: Connect the positive terminal of the battery to one probe. The other probe connects through the buzzer (or LED with resistor) to the negative terminal. When the probes touch a continuous path, the circuit completes, and the buzzer sounds or the LED lights up.

- Assemble on a PCB: Solder the components onto a small perfboard, ensuring secure connections. Keep the layout neat to avoid accidental shorts.

- Test Your Tester: Touch the probes together to confirm the buzzer or LED activates. Then, use it on a PCB to check for connectivity between pads or traces.

Usage Tip: This tool is perfect for finding open circuits or verifying solder joints. If the buzzer doesn’t sound when testing a trace, you’ve likely found a break in the connection.

Project 2: Creating a Voltage Probe for Signal Measurement

A voltage probe is a step up in complexity and an excellent piece of homemade PCB measurement equipment. It allows you to measure DC voltages across components or test points on your PCB, helping with debugging.

Materials Needed

- Small digital voltmeter module (available online for under $5)

- Two test probes or alligator clips

- Enclosure (optional, for safety and durability)

- Wires and soldering supplies

- Small PCB or perfboard

Steps to Build

- Connect the Voltmeter: Solder wires from the voltmeter’s input terminals to your probes. Ensure proper polarity—red for positive, black for negative.

- Mount Components: Secure the voltmeter module and wires onto a PCB or inside an enclosure. This protects the setup and makes it portable.

- Calibrate and Test: Use a known voltage source (like a 9V battery) to verify the voltmeter reads accurately (e.g., 9.0V ± 0.1V). Adjust if necessary, following the module’s instructions.

Usage Tip: Use this tool to measure voltage drops across resistors or check if a microcontroller pin outputs the expected voltage (e.g., 3.3V or 5V for common logic levels). It’s invaluable for basic PCB troubleshooting techniques.

Project 3: Designing a Basic Signal Generator

A signal generator creates test signals (like square or sine waves) to stimulate your circuits. This is a more advanced project for DIY PCB testing tools but incredibly useful for testing amplifiers or filters.

Materials Needed

- 555 timer IC

- Resistors (1kΩ, 10kΩ)

- Capacitors (10nF, 100nF)

- Potentiometer (10kΩ for frequency adjustment)

- Small PCB or breadboard

- 9V battery and connector

Steps to Build

- Circuit Design: Use the 555 timer in astable mode to generate a square wave. Connect resistors and capacitors as per standard 555 timer schematics to set a frequency range (e.g., 1Hz to 10kHz). The potentiometer allows you to adjust the frequency.

- Assemble on PCB: Solder components onto a PCB, ensuring correct pin connections for the 555 timer. Double-check for shorts or loose joints.

- Test the Output: Use a multimeter or a small speaker to verify the signal. At 1kHz, you should hear a tone if connected to a speaker, confirming the generator works.

Usage Tip: Connect the output to your circuit’s input to test response. For instance, feed a 1kHz signal into an audio amplifier to check for distortion or gain issues. This tool is a cornerstone of PCB testing for hobbyists.

Basic PCB Troubleshooting Techniques for Hobbyists

Once you have your DIY PCB testing tools, knowing how to use them for troubleshooting is key. Here are some basic PCB troubleshooting techniques to identify and fix common issues:

- Visual Inspection: Look for obvious problems like burnt components, cracked traces, or poor solder joints. A magnifying glass can help spot tiny defects.

- Continuity Check: Use your homemade continuity tester to verify connections. If a trace between two points doesn’t beep, there’s likely a break.

- Voltage Testing: Measure voltages at key points using your voltage probe. Compare readings against expected values (e.g., a 5V regulator should output close to 5V).

- Signal Testing: Use your signal generator to input a known signal and trace it through the circuit. If the signal drops or distorts at a specific point, you’ve found a potential fault.

By systematically applying these techniques, you can pinpoint issues like a faulty capacitor (showing incorrect voltage) or a broken trace (failing continuity).

Tips for Designing Effective Homemade PCB Measurement Equipment

Building homemade PCB measurement equipment requires attention to detail. Here are some tips to ensure your tools are reliable and safe:

- Use Quality Components: Cheap or damaged parts can lead to inaccurate readings. For example, a capacitor rated for 16V should not be used in a 20V circuit as it risks failure.

- Keep It Simple: Start with basic designs like the ones above before moving to complex tools like oscilloscopes.

- Label Everything: Mark probes and outputs clearly (e.g., “Positive Probe”) to avoid mistakes during testing.

- Test in Safe Ranges: Work with low voltages (below 12V) and currents (under 100mA) to minimize risks to yourself and your equipment.

Challenges and Solutions in DIY PCB Testing Tools

While building DIY PCB testing tools is rewarding, you might face challenges. Here are common issues and how to overcome them:

- Inaccurate Measurements: If your voltage probe reads inconsistently, check for loose connections or calibrate it against a known source. A deviation of more than 0.2V might indicate a problem.

- Signal Noise: If your signal generator output is noisy, add a small capacitor (e.g., 0.1μF) across the power supply to filter interference.

- Durability Issues: Homemade tools can break easily. Use an enclosure or reinforce connections with heat-shrink tubing for added protection.

Scaling Up: Next Steps for Advanced Hobbyists

Once you’ve mastered these basic projects, consider advancing your skills with more complex homemade PCB measurement equipment. Ideas include:

- Mini Oscilloscope: Build a low-cost scope using a microcontroller to visualize waveforms up to 10kHz.

- Resistance Meter: Design a circuit to measure resistance values precisely, useful for checking resistors or traces.

- Frequency Counter: Create a tool to measure the frequency of signals, ideal for testing oscillators.

These projects require more components and programming knowledge but build on the foundation of simple PCB testing circuits.

Conclusion: Empower Your Hobby with DIY Testing Tools

Creating your own DIY PCB testing tools is a practical and fulfilling way to enhance your electronics hobby. From a basic continuity tester to a versatile signal generator, these projects equip you with the means to tackle PCB testing for hobbyists effectively. By applying basic PCB troubleshooting techniques and building homemade PCB measurement equipment, you not only save money but also deepen your understanding of circuits. Start with the simple projects outlined here, and soon you’ll be confident enough to design even more advanced tools tailored to your needs. Dive into these builds and take control of your PCB testing journey today!

ALLPCB

ALLPCB