If you're diving into multi-layer PCB projects, choosing the right material is crucial for performance, cost, and reliability. Whether you're a hobbyist working on DIY electronics or a professional engineer designing complex circuits, understanding PCB materials like FR4 and other options can make or break your project. In this comprehensive guide, we’ll explore the best multi-layer PCB material options, focusing on popular choices like FR4 PCB, and provide actionable insights for selecting materials that suit your needs in electronics components design.

Why PCB Material Choice Matters for Multi-Layer Projects

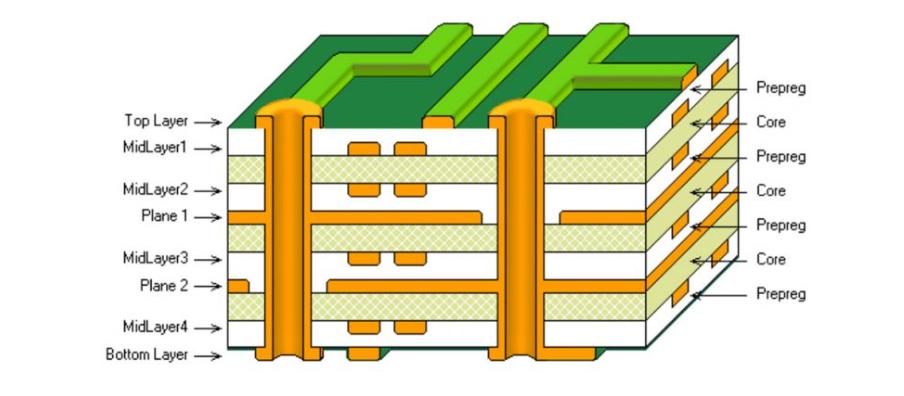

When it comes to multi-layer PCBs, which often involve intricate designs with several stacked layers (sometimes 4, 8, or even 16+), the material you choose directly impacts signal integrity, thermal management, and durability. Multi-layer boards are used in everything from smartphones to industrial equipment, so the stakes are high. A poor material choice can lead to issues like signal loss, overheating, or mechanical failure under stress.

The right PCB material ensures:

- Stable electrical performance with controlled impedance (often critical for high-speed signals above 1 GHz).

- Effective heat dissipation, especially in dense designs with power components.

- Mechanical strength to handle manufacturing and operational stresses.

- Cost-effectiveness for your project budget, whether it’s a one-off DIY build or mass production.

In the following sections, we’ll break down the most common materials for multi-layer projects, starting with the industry standard, FR4, and moving into alternatives for specialized applications. Let’s dive into the world of PCB materials DIY enthusiasts and professionals alike can rely on.

What is FR4 PCB Material and Why is it So Popular?

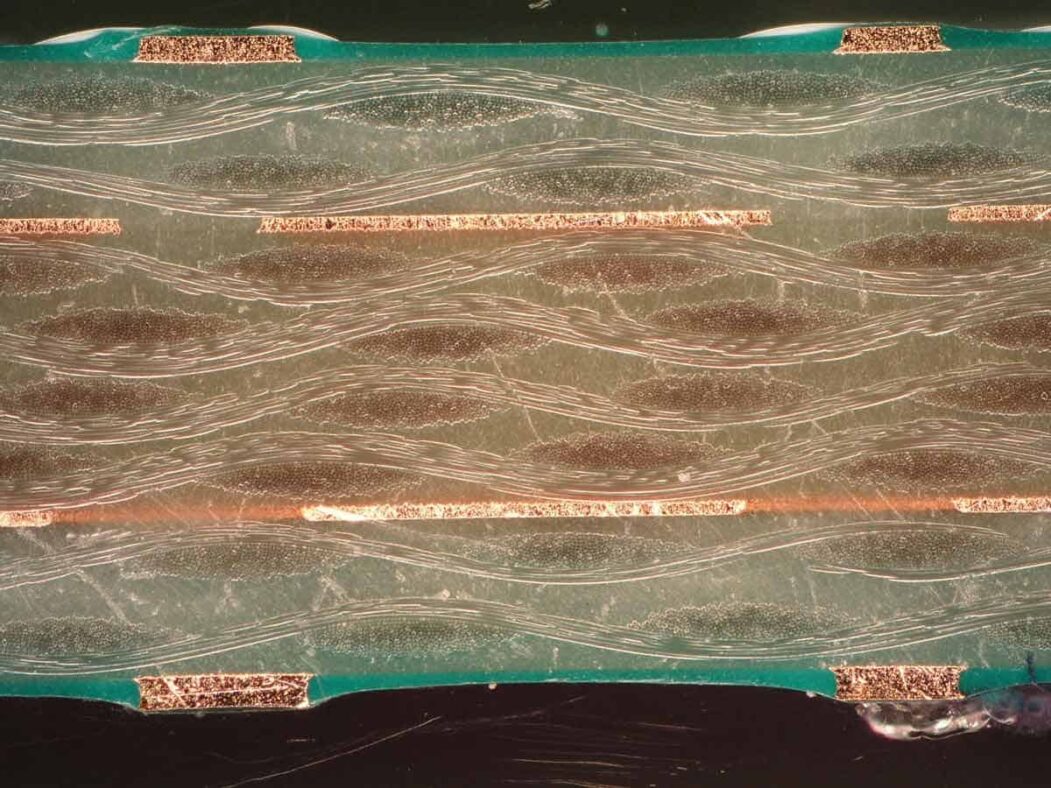

FR4 is the go-to material for most PCB projects, including multi-layer designs. But what exactly is it? FR4 stands for "Flame Retardant 4," a grade of glass-reinforced epoxy laminate. It consists of woven fiberglass cloth bonded with an epoxy resin that’s flame-resistant, making it a safe and durable choice for electronics.

Here are some key properties of FR4 that make it ideal for multi-layer projects:

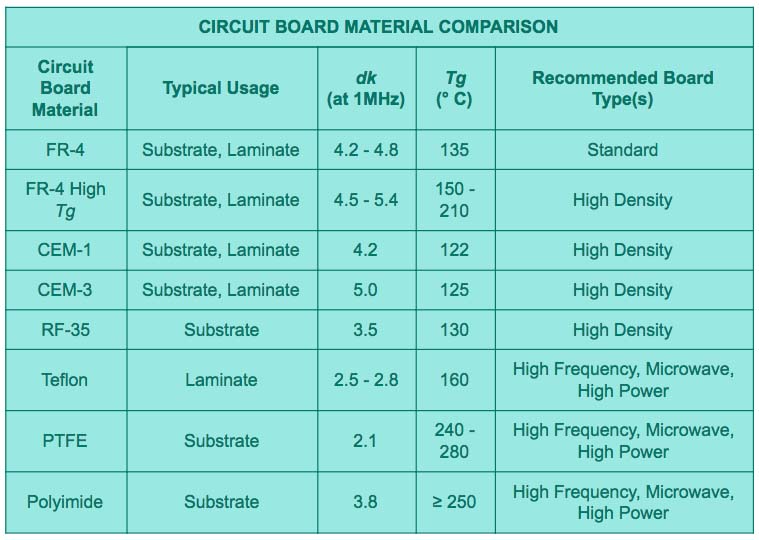

- Dielectric Constant (Dk): Typically around 4.5 at 1 MHz, which supports stable signal transmission in most consumer electronics.

- Thermal Resistance: FR4 can handle temperatures up to 130°C (depending on the specific grade), suitable for many applications.

- Mechanical Strength: Its fiberglass reinforcement provides excellent rigidity, preventing warping in multi-layer stacks.

- Cost: FR4 is one of the most affordable materials, often costing just a fraction of high-performance alternatives.

For DIY electronics components and small-scale projects, FR4 strikes a perfect balance between performance and price. It’s widely available in various thicknesses (from 0.2mm to 3.2mm) and can support multi-layer designs up to 8 or 10 layers without significant issues. However, for high-frequency applications (above 5 GHz) or extreme thermal environments, FR4 may show limitations like higher signal loss or reduced thermal conductivity.

Other Multi-Layer PCB Material Options Beyond FR4

While FR4 is the standard, it’s not always the best fit for every multi-layer project. Depending on your design requirements, other materials might offer better performance for specific needs like high-speed signals, thermal management, or flexibility. Below are some popular alternatives to consider for your PCB materials DIY or professional projects.

1. High-Tg FR4 for Enhanced Thermal Performance

High-Tg (Glass Transition Temperature) FR4 is a variation of standard FR4 with a higher thermal tolerance, often exceeding 170°C compared to the standard 130°C. This makes it a great choice for multi-layer PCBs in environments with elevated temperatures, such as automotive or industrial applications.

- Best Use Case: Projects requiring lead-free soldering, which often involves higher temperatures (up to 260°C during reflow).

- Cost: Slightly more expensive than standard FR4 but still budget-friendly.

2. Polyimide for Flexibility and High Temperatures

Polyimide materials are known for their flexibility and ability to withstand extreme temperatures (up to 260°C or more). While often used in flexible PCBs, polyimide can also be incorporated into rigid-flex multi-layer designs where space constraints or dynamic movement are factors.

- Dielectric Constant (Dk): Around 3.5, better than FR4 for high-frequency signals.

- Best Use Case: Wearable electronics or aerospace applications with multi-layer needs.

- Cost: Significantly higher than FR4, often 2-3 times the price per square inch.

3. PTFE-Based Materials for High-Frequency Applications

Polytetrafluoroethylene (PTFE) materials, often reinforced with ceramic or glass, are designed for high-frequency applications where signal integrity is critical. They have a much lower dielectric constant (around 2.1-3.0) and loss tangent compared to FR4, minimizing signal loss at frequencies above 10 GHz.

- Best Use Case: RF circuits, 5G technology, and microwave applications in multi-layer designs.

- Cost: Expensive, often 5-10 times the cost of FR4, making it less ideal for budget-conscious DIY projects.

4. Metal-Core Materials for Superior Heat Dissipation

Metal-core PCBs (MCPCBs) use a metal base, typically aluminum or copper, to improve heat dissipation. These are often used in multi-layer designs for power electronics where components generate significant heat.

- Thermal Conductivity: Up to 1-3 W/mK for aluminum cores, far superior to FR4’s 0.3 W/mK.

- Best Use Case: LED lighting, power converters, and motor control systems.

- Cost: Higher than FR4 but more affordable than PTFE-based options.

Factors to Consider When Choosing PCB Materials for Multi-Layer Projects

Selecting the right material for your multi-layer PCB involves evaluating several key factors. Here’s a breakdown of what to consider to ensure your design meets performance and budget goals, especially for electronics components in DIY or professional settings.

1. Electrical Requirements

Your project’s electrical needs are a primary concern. For high-speed digital circuits or RF applications, materials with a low dielectric constant and low loss tangent are essential to prevent signal degradation. For example, at 10 GHz, FR4 might result in a signal loss of 0.02-0.03 dB per inch, while PTFE materials can reduce this to under 0.01 dB per inch.

2. Thermal Management

Heat dissipation becomes more challenging as the number of layers increases. If your multi-layer PCB will operate in high-temperature environments or include power-hungry components, consider materials like High-Tg FR4 or metal-core options to avoid delamination or component failure.

3. Mechanical Stability

Multi-layer PCBs often face mechanical stress during manufacturing (drilling, soldering) and operation. FR4 and similar rigid materials provide the necessary strength to prevent warping or cracking, especially in boards with 6 or more layers.

4. Cost Constraints

For most DIY enthusiasts and small-scale projects, cost is a major factor. FR4 remains the most economical choice, with prices often starting at $0.10-$0.20 per square inch for standard grades. High-performance materials can quickly drive up costs, so weigh the benefits against your budget.

5. Manufacturing Compatibility

Ensure the material you choose is compatible with your manufacturing process. Some high-performance materials require specialized equipment or processes, which might not be available for small-scale or DIY production. FR4, on the other hand, is widely supported by most fabrication houses.

Tips for DIY Enthusiasts Working with Multi-Layer PCB Materials

If you’re a hobbyist tackling PCB materials DIY projects, multi-layer designs might seem intimidating, but they’re achievable with the right approach. Here are some practical tips to help you succeed:

- Start with FR4: It’s the easiest and most cost-effective material to work with for beginners. Most online design tools and fabrication services support FR4 by default.

- Keep Layer Count Low: For your first multi-layer project, stick to 4-6 layers to minimize complexity and cost. A 4-layer FR4 board often costs just 20-30% more than a 2-layer board.

- Use Standard Thicknesses: Opt for common FR4 thicknesses like 1.6mm to ensure compatibility with components and manufacturing processes.

- Test Signal Integrity: If your project involves high-speed signals, use free simulation software to check for impedance mismatches before fabrication.

- Plan for Heat: Add thermal vias or heat sinks if your design includes power components, even with FR4, to prevent overheating.

By starting simple and leveraging widely available materials like FR4, you can build reliable multi-layer PCBs without breaking the bank.

Conclusion: Finding the Right Material for Your Multi-Layer PCB Project

Choosing the right PCB material for your multi-layer projects is a critical step that influences everything from performance to cost. FR4 PCB remains the most popular choice due to its versatility, affordability, and reliability for most applications, making it a go-to for both DIY enthusiasts and professionals. However, depending on your project’s specific needs—be it high-frequency performance, thermal management, or flexibility—alternatives like High-Tg FR4, polyimide, PTFE-based materials, or metal-core options might be worth the investment.

By carefully evaluating factors like electrical requirements, thermal needs, and budget, you can select the best multi-layer PCB material options for your design. Whether you’re crafting electronics components for a hobby project or engineering a complex industrial system, the right material sets the foundation for success. Take the time to experiment with different materials, starting with accessible options like FR4, and scale up as your expertise and project demands grow.

ALLPCB

ALLPCB