In the fast-evolving world of surgical robotics, compact and efficient designs are critical for precision and performance. High-Density Interconnect (HDI) PCBs are at the heart of this revolution, enabling smaller, more powerful systems through advanced technologies like microvia PCB manufacturing and high-density PCB routing. But how exactly do HDI PCBs transform surgical robots? This blog explores the role of HDI PCBs in creating compact designs for surgical robotics, diving into component miniaturization, manufacturing techniques, and their impact on medical technology.

What Are HDI PCBs and Why Do They Matter for Surgical Robotics?

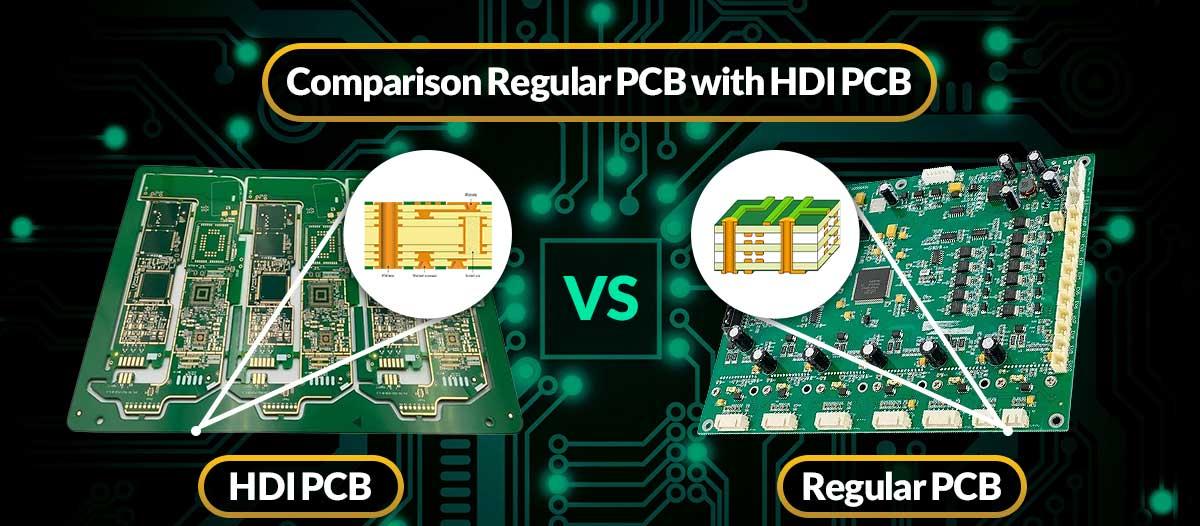

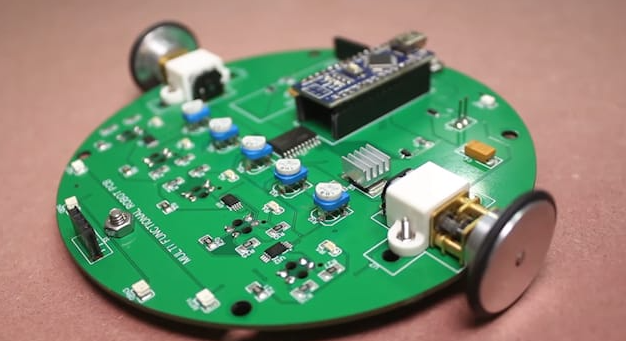

High-Density Interconnect (HDI) PCBs are specialized circuit boards designed to pack more components into a smaller space. Unlike traditional PCBs, HDI boards use finer lines, smaller vias (like microvias), and denser layouts to achieve higher functionality without increasing the board's size. This makes them ideal for applications where space and precision are paramount, such as in surgical robots.

In surgical robotics, where devices must fit into tight spaces and perform complex tasks with pinpoint accuracy, HDI PCBs play a vital role. They support compact PCB design by allowing engineers to integrate advanced sensors, actuators, and control systems into smaller footprints. This not only reduces the overall size of robotic systems but also enhances their reliability and performance during delicate medical procedures.

The Role of Compact PCB Design in Surgical Robotics

Compact PCB design is a game-changer for surgical robotics. These systems often operate in confined spaces, such as inside the human body during minimally invasive surgeries. A smaller, more efficient PCB allows robotic arms, cameras, and tools to be miniaturized without sacrificing functionality.

For instance, a surgical robot's control system might need to process signals at high speeds to ensure real-time responses during operations. HDI PCBs, with their ability to support high-density PCB routing, reduce signal delays by minimizing the distance between components. This can result in signal transmission speeds that are up to 30% faster compared to traditional boards, ensuring smoother and more precise robotic movements.

Additionally, compact designs mean lighter devices, which are easier for surgeons to maneuver. By using HDI PCBs, manufacturers can reduce the weight of robotic systems by as much as 20%, improving ergonomics and reducing fatigue during long procedures.

Microvia PCB Manufacturing: The Backbone of HDI Technology

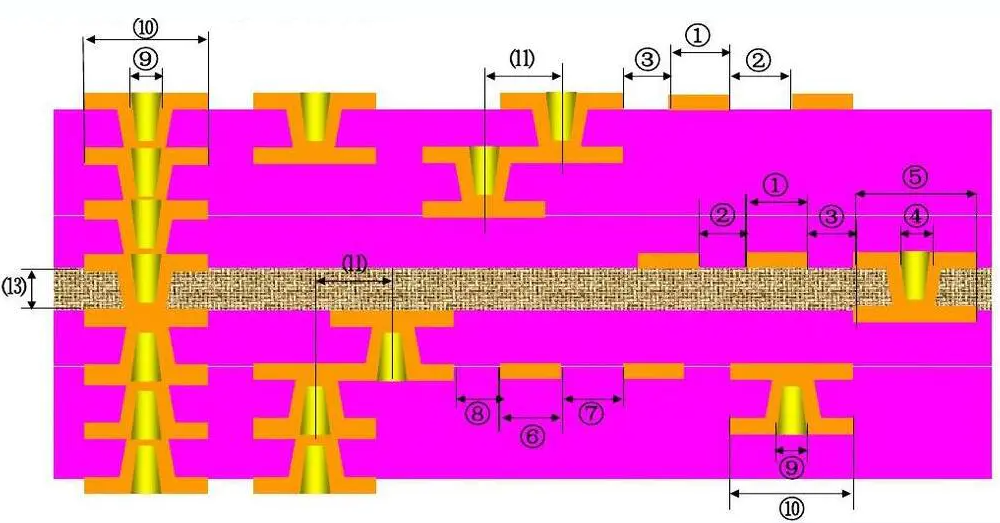

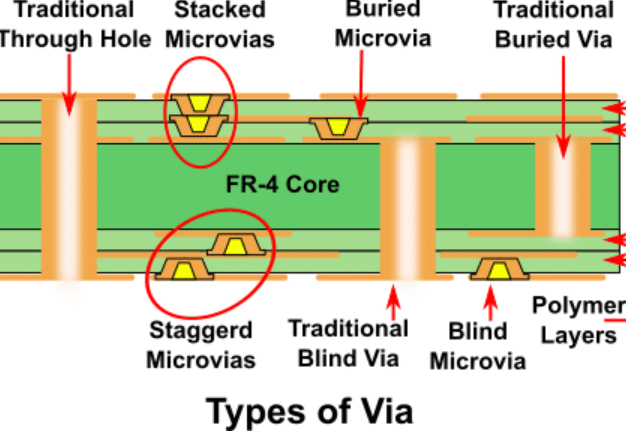

One of the key features of HDI PCBs is the use of microvias—tiny holes that connect different layers of the board. Unlike standard vias, which can be as large as 0.3 mm in diameter, microvias are often less than 0.15 mm, allowing for much tighter spacing and higher component density.

Microvia PCB manufacturing involves advanced techniques like laser drilling to create these small, precise holes. This process ensures that connections between layers are reliable, even in the most compact designs. For surgical robots, this means that critical components like microcontrollers and sensors can be placed closer together, reducing the overall size of the system while maintaining signal integrity. In fact, microvias can lower impedance values by up to 15%, ensuring cleaner signals for high-speed data transfer.

The manufacturing process also allows for stacked and staggered microvias, which further increase the density of connections. This is especially useful in multi-layer boards used in surgical robotics, where space constraints demand innovative solutions.

High-Density PCB Routing: Maximizing Space and Performance

High-density PCB routing is another critical aspect of HDI technology that directly impacts surgical robotics. Routing refers to the arrangement of electrical connections on the board, and in HDI PCBs, these connections are much finer and more closely spaced than in traditional designs. Line widths in HDI boards can be as narrow as 0.075 mm, compared to 0.2 mm or more in standard PCBs, allowing for more traces in a smaller area.

For surgical robots, high-density routing ensures that complex circuits can fit into tight spaces without interference or signal loss. This is crucial for integrating multiple functions—like motor control, sensor feedback, and data processing—into a single, compact unit. Efficient routing also reduces electromagnetic interference (EMI), which can disrupt sensitive medical equipment. By optimizing trace layouts, HDI PCBs can cut EMI by up to 25%, ensuring reliable operation in the operating room.

Moreover, high-density routing supports the integration of advanced features like 5G connectivity for real-time data transmission during surgeries. This capability is essential for remote robotic surgeries, where split-second decisions rely on seamless communication between the surgeon and the robotic system.

Component Miniaturization for Surgical Robots: Smaller, Smarter Systems

Component miniaturization for surgical robots is a direct benefit of HDI PCB technology. By using smaller components and denser layouts, engineers can design robotic systems that are not only compact but also more powerful. For example, miniaturized sensors and actuators can be embedded into robotic tools, enabling precise movements with tolerances as tight as 0.05 mm—critical for delicate procedures like reconnecting blood vessels or nerves.

HDI PCBs facilitate this miniaturization by providing the necessary infrastructure for tiny components. Surface-mount technology (SMT) and fine-pitch components, which can have lead spacings as small as 0.4 mm, are commonly used in HDI designs. This allows for the integration of advanced microprocessors and memory chips into surgical robots, supporting features like machine learning algorithms for enhanced precision.

The impact of miniaturization goes beyond size. Smaller components often consume less power, which is vital for battery-operated robotic systems. HDI PCBs can reduce power consumption by up to 10% through optimized layouts, extending the operational time of portable surgical devices.

Benefits of HDI PCBs in Surgical Robotics

The adoption of HDI PCBs in surgical robotics offers several tangible benefits that enhance both design and performance. Here are some of the most significant advantages:

- Reduced Size and Weight: HDI PCBs can shrink the footprint of electronic systems by up to 60%, making surgical robots more compact and easier to handle.

- Improved Precision: With faster signal transmission and lower impedance, HDI boards support the high precision required for microsurgeries, achieving movement accuracies within 0.1 mm.

- Enhanced Reliability: The use of microvias and high-density routing minimizes connection failures, ensuring consistent performance during critical operations.

- Support for Advanced Features: HDI technology enables the integration of cutting-edge functionalities, such as AI-driven decision-making and real-time imaging, into surgical systems.

- Cost Efficiency in the Long Run: While HDI PCBs may have higher initial manufacturing costs, their ability to reduce device size and improve performance can lower overall production expenses over time.

Challenges in Implementing HDI PCBs for Surgical Robotics

Despite their many advantages, implementing HDI PCBs in surgical robotics comes with certain challenges. The manufacturing process for HDI boards, especially microvia PCB manufacturing, requires specialized equipment and expertise, which can increase costs. Laser drilling and precise alignment of layers demand high accuracy to avoid defects, as even a 0.01 mm misalignment can lead to signal issues.

Additionally, the complexity of high-density PCB routing can make design and testing more time-consuming. Engineers must carefully balance density with thermal management, as tightly packed components can generate excess heat. Effective heat dissipation solutions, such as thermal vias or advanced materials, are often necessary to maintain performance, adding another layer of complexity to the design process.

However, advancements in manufacturing technology are steadily addressing these challenges. Automated design tools and improved materials are making it easier to produce reliable HDI PCBs tailored for surgical robotics, ensuring that the benefits outweigh the hurdles.

Future Trends: HDI PCBs and the Next Generation of Surgical Robotics

The future of HDI PCBs in surgical robotics looks incredibly promising. As medical technology continues to advance, the demand for even smaller, smarter, and more precise robotic systems will grow. HDI PCBs are expected to evolve with trends like the following:

- Integration with AI and IoT: HDI PCBs will support more sophisticated AI algorithms and Internet of Things (IoT) connectivity, enabling surgical robots to learn from past procedures and communicate seamlessly with other medical devices.

- Advanced Materials: New substrate materials with better thermal and electrical properties will enhance the performance of HDI PCBs, allowing them to handle higher frequencies and power levels for next-gen robotics.

- 3D PCB Designs: The shift toward three-dimensional PCB layouts will further increase density and functionality, pushing the boundaries of compact PCB design for surgical applications.

These trends indicate that HDI PCBs will remain a cornerstone of innovation in surgical robotics, driving the development of systems that are not only more compact but also more intelligent and efficient.

How ALLPCB Supports HDI PCB Solutions for Surgical Robotics

At ALLPCB, we understand the unique demands of surgical robotics and the critical role that HDI PCBs play in this field. Our advanced manufacturing capabilities ensure that every board meets the highest standards of precision and reliability. From microvia drilling to high-density routing, we offer tailored solutions to support compact PCB design and component miniaturization for surgical robots.

Our team of experts works closely with engineers to optimize layouts, reduce signal interference, and achieve the smallest possible footprints without compromising performance. With a commitment to quality and innovation, we help bring cutting-edge surgical robotic systems to life, ensuring they meet the stringent requirements of the medical industry.

Conclusion: The Impact of HDI PCBs on Surgical Robotics

High-Density Interconnect (HDI) PCBs are transforming surgical robotics by enabling compact, efficient, and high-performing designs. Through technologies like microvia PCB manufacturing, high-density PCB routing, and component miniaturization, HDI boards make it possible to create smaller robotic systems that deliver exceptional precision and reliability. As the medical field continues to push for minimally invasive solutions, the role of HDI PCBs will only grow, paving the way for smarter and more advanced surgical tools.

By leveraging the power of HDI technology, manufacturers can overcome the challenges of space constraints and performance demands, ultimately improving patient outcomes and advancing healthcare. At ALLPCB, we’re proud to be part of this revolution, providing the tools and expertise needed to build the future of surgical robotics.

ALLPCB

ALLPCB