PCB Board Warpage Reasons and Treatment

People in the industry are more aware of the impact of PCB warpage. If it makes the SMT electronic component installation impossible, or the electronic component (including the integrated block) is in poor contact with the printed circuit board solder joint, or the electronic component is not cut or cut to the substrate when the leg is mounted. Some parts of the substrate are not in contact with the solder surface and are not soldered to the solder.

One of the causes of warpage of printed circuit boards is that the substrate (copper clad) may be warped, but during the processing of printed circuit boards, thermal stress, chemical influences, and improper production processes may also cause printing. The circuit board produces warpage.

Therefore, for printed circuit board manufacturers, the first is to prevent the printed circuit board from warping during processing; and then there is a suitable and effective treatment method for PCB boards that have already appeared warped.

1. Prevent the substrate from being warped due to improper inventory

a. Since the copper clad laminate is in the process of storage, the moisture absorption area will increase the warpage, and the moisture absorption area of the single-sided copper clad laminate is large. If the inventory environment humidity is high, the single-sided copper clad laminate will significantly increase the warpage. The moisture of the double-sided copper clad plate can only penetrate from the end face of the product, the moisture absorption area is small, and the warpage changes slowly.

Therefore, for the copper clad laminate without moisture-proof packaging, pay attention to the warehouse conditions, minimize the humidity of the warehouse and avoid the bare copper clad plate to avoid the warpage of the copper clad laminate during storage.

b.Improper placement of copper clad laminates will increase warpage. If the vertical or copper clad plate is pressed with heavy objects, poor placement, etc. will increase the copper plate warpage deformation.

2. Avoid warpage caused by improper design of printed circuit board circuit or improper processing technology.

If the PCB pattern of the conductive circuit is not balanced or the circuit on both sides of the PCB is obviously asymmetrical, one side has a large area of copper, which forms a large stress, causing the PCB to warp. The processing temperature is high or large in the PCB process. Shocks and the like can cause the PCB to warp. For the impact of improper boarding stocks, the PCB factory is better able to solve the problem, improve the storage environment and eliminate vertical and avoid heavy pressure. For PCB boards with a large area of copper, it is best to mesh the copper foil to reduce stress.

3. Eliminate substrate stress and reduce PCB warpage during processing

Since the substrate is subjected to heat many times during the processing of the PCB and is subjected to various chemicals. For example, after the substrate is etched, it should be washed, dried, and heated. When the pattern is electroplated, the plating is hot. After printing the green oil and printing the logo characters, it should be dried by heating or dried with UV light. When the hot air is sprayed, the substrate is subjected to thermal shock. Also great and so on. These processes can cause warpage of the PCB board.

4. When wave soldering or dip soldering, the solder temperature is high and the operation time is long, which will increase the substrate warpage. For the improvement of the wave soldering process, the electronics assembly factory needs to cooperate.

Since stress is the main cause of substrate warpage, if the copper clad board is used before the board is put into use, it is also considered that this method is beneficial to reduce the warpage of the PCB board.

The function of the baking plate is to sufficiently relax the stress of the substrate, thereby reducing the warpage deformation of the substrate in the PCB process.

The method of seesaw is: the conditional PCB factory uses large oven rafts. A large stack of copper clad laminates is fed into the oven prior to production, and the copper clad laminate is baked for several hours to ten hours at a temperature near the glass transition temperature of the substrate. The PCB board produced by the copper clad laminate is relatively small in warpage and the product qualification rate is much higher.

For some small PCB factories, if there is not such a large oven, the substrate can be cut and then baked, but the weight should be pressed against the plate to make the substrate maintain a flat state during the stress relaxation process. The temperature of the baking sheet should not be too high, and the substrate will change color when the temperature is too high. It should not be too low, and the temperature is too low to take a long time to relax the substrate stress.

Printed Circuit Board Warping And Leveling Method

1. Flatten Warped Plate in PCB Process

In the PCB process, the plate with a relatively large warpage is picked out and leveled by a roll-type leveler, and then put into the next process. Many PCB manufacturers believe that this practice is effective for reducing the warpage ratio of PCB finished boards.

2. PCB Finished Board Warping And Leveling Method

For completed, the warpage is obviously out of tolerance, and the PCB can not be leveled by the roll-type leveling machine. Some PCB factories put it into a small press (or similar fixture) to press the warped PCB board. Staying for a few hours to ten hours for cold pressing and leveling, from the practical application, the effect of this practice is not very obvious. First, the effect of leveling is not great, and the other is that the flattened board is easy to rebound (ie, the warpage is restored).

Some PCB factories will heat the small press to a certain temperature, then heat-press the flattened PCB board, the effect will be better than the cold pressure, but if the pressure is too large, the wire will be deformed; if the temperature is too high It will produce defects such as discoloration of pine perfume and its discoloration. Moreover, whether it is cold press leveling or hot press leveling, it takes a long time (a few hours to a dozen hours) to see the effect, and the proportion of warpage bounce of the flattened PCB board is also high. Is there a better leveling method?

3. Warped PCB Board Bow Mold Hot Pressing And Leveling Method

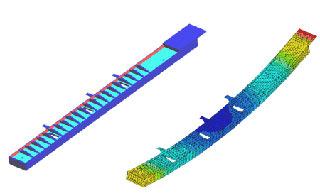

According to the mechanical properties of polymer materials and many years of work practice, this paper recommends the hot stamping and flattening method of bow mold. According to the area of the PCB to be leveled, a simple bow mold (see Figure 1) is used. Here, two types of leveling operations are proposed.

a. Clamp The Warped PCB Board Into The Bow Mold And Put It into The Oven Baking And Leveling Method:

The warped PCB board is curved to face the curved surface of the mold, and the fixture screw is adjusted to deform the PCB board in the opposite direction of the warpage, and then the mold with the PCB board is placed in an oven heated to a certain temperature to be baked. Bake for a while. Under the heated condition, the substrate stress gradually relaxes, and the deformed PCB board is restored to a flat state. However, the baking temperature should not be too high, so as to prevent the pine perfume from changing color or the substrate turning yellow. However, the temperature should not be too low, and it takes a long time to completely relax the stress at a lower temperature.

Generally, the substrate glass transition temperature can be used as the reference temperature for baking, and the glass transition temperature is the phase transition point of the resin, at which the polymer segments can be rearranged to make the substrate stress sufficiently relaxed.

Because the leveling effect is obvious. The advantage of flattening with the bow mold is that the investment is very small. The ovens are all available in the PCB factory. The leveling operation is very simple. If the number of warped plates is relatively large, it is enough to make a few bow molds. You can put them in the oven once. A few molds, and the drying time is relatively short (about tens of minutes), so the leveling work efficiency is relatively high.

b. The PCB Board is Softened And Then Clamped into The Bow Mold to Press And Level The Method:

For PCB boards with relatively small warpage deformation, the PCB board to be leveled can be placed in an oven that has been heated to a certain temperature (the temperature setting can be determined by referring to the glass transition temperature of the substrate and the substrate is baked in the oven for a certain period of time. Observe the softening condition to determine. Generally, the baking temperature of the fiberglass cloth substrate is higher, the baking temperature of the paper substrate can be lower; the baking temperature of the thick plate can be slightly higher, and the baking temperature of the thin plate can be slightly lower.

For the PCB board that has been sprayed with pine perfume, the baking temperature should not be too high.) Bake for a certain period of time, then take a few sheets to a dozen sheets, clip into the bow mold, adjust the pressure screw, and make the PCB board slightly The warping is deformed in the opposite direction. After the plate is cooled and shaped, the mold can be unloaded and the flattened PCB board can be taken out.

Some users do not know the glass transition temperature of the substrate. The baking reference temperature is recommended here. The baking temperature of the paper substrate is 110 ° C ~ 130 ° C, and the FR-4 is 130 ° C ~ 150 ° C. During the leveling, several small tests were performed on the selected baking temperature and baking time to determine the baking temperature and baking time of the leveling. The baking time is longer, the substrate is well-baked, the leveling effect is better, and the warpage of the PCB board is less after the leveling.

The warpage of the PCB board after the flattening of the bow mold is low; even after wave soldering, it can basically maintain a flat state; the influence on the appearance color of the PCB board is also small.

PCB board warpage is a headache for PCB manufacturers. It not only reduces the yield but also affects the delivery time. If the arc-shaped mold is used for thermal leveling, and the leveling process is reasonable and suitable, the warped PCB board can be leveled to solve the problem of delivery time.

My Message

My Message

Suggestions

Suggestions