Wave soldering and reflow soldering are two common soldering methods. Let's talk about the difference between wave soldering and reflow soldering.

For the technology of PCB Surface mounts, it is often name as SMT; it is an electronic assembly technology. SMT products have many advantages of compact structure, small-size, and many kinds of resistance, impact resistance, high-frequency values and qualified production efficiency.

The typical surface mount process is divided into three steps: applying solder paste - mounting components - reflow soldering

Step1: Applying Solder Paste

The purpose is to apply an appropriate amount of solder paste uniformly on the pads of the PCB to ensure that the pads corresponding to the PCB components and the PCB achieve good electrical connection during reflow soldering and have sufficient mechanical strength.

Solder paste is a paste with a certain viscosity and good touch characteristics, which is a mixture of alloy powder, paste flux and some additives. At normal temperature, since the solder paste has a certain viscosity, the electronic components can be pasted on the pads of the PCB.

In the case where the tilt angle is not too large and there is no external force collision, the general components will not move when soldering. When the paste is heated to a certain temperature, the alloy powder in the solder paste melts and flows, the liquid solder wets the soldering end of the component and the PCB pad, and the soldered end and the pad of the cooled component are interconnected by the solder to form an electrical and mechanical connected solder joints.

Solder paste is applied to the pad by special equipment. The equipment has:

Automatic printing machine, semi-automatic printing machine, manual printing table, semi-automatic solder paste dispenser, etc.

Application method application situation advantage point

Machine printing large batch size, tight delivery period, and sufficient funds for large-scale production, high production efficiency, complicated use procedures, and large investment.

Manual printing Medium and small batch production, product development, easy operation, low cost, manual positioning, mass production.

Manual Drip Coating R&D of ordinary circuit boards, repairing pad solder pastes can be developed and produced without auxiliary equipment. It is only suitable for component drop with pad pitch of 0.6mm or more.

Step 2: Mounting Components

In this process, the chip components are accurately mounted on the surface of the PCB on which the solder paste or the paste is printed by using a placement machine or a manual.

There are two mounting methods, the comparison is as follows:

1. Application method application situation advantage point

Machine Mounting Large batch size, tight delivery cycle Suitable for mass production

2. Use of complicated processes and large investment

Manual placement Small and medium batch production, product development Easy to operate, low cost Production efficiency depends on the proficiency of the operators.

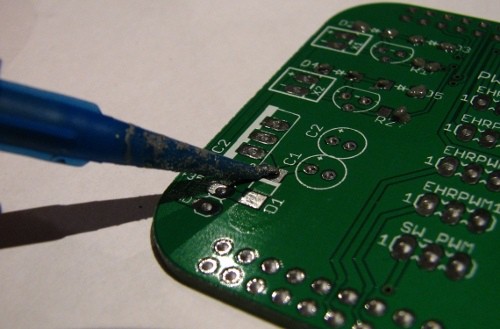

Manual placement of the main tools: vacuum pen, tweezers, IC suction aligner, low power stereo microscope or magnifying glass.

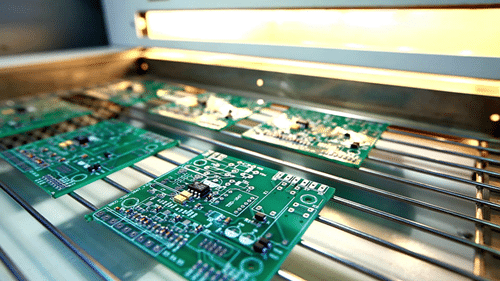

Step3: Reflow Soldering

Reflow soldering is a literal translation of the English Reflow Soldering that re-melts the solder pre-dispensed onto the printed circuit board pads to achieve mechanical and electrical soldering of the surface-mount components or between the pins and the printed circuit board pads. Connected soldering.

The principle of reflow soldering is analyzed from the SMT temperature characteristic curve (see figure). When the PCB enters the preheating temperature range of 140 ° C to 160 ° C, the solvent and gas in the solder paste evaporate. At the same time, the flux in the solder paste wets the pad, the soldering end of the component and the lead, and the solder paste softens.

Collapse, covering the pad, isolating the pad, component leads from oxygen; and allowing the surface mount component to be fully preheated, and then entering the soldering zone, the temperature is rapidly increasing at an international standard of 2-3 ° C per second.

The rise causes the solder paste to reach a molten state, and the liquid solder is wetted, diffused, diffused, and reflowed at the soldering interface to form a metal compound on the solder pad, forming a solder joint; and finally the PCB enters the cooling zone. The solder joints solidify.

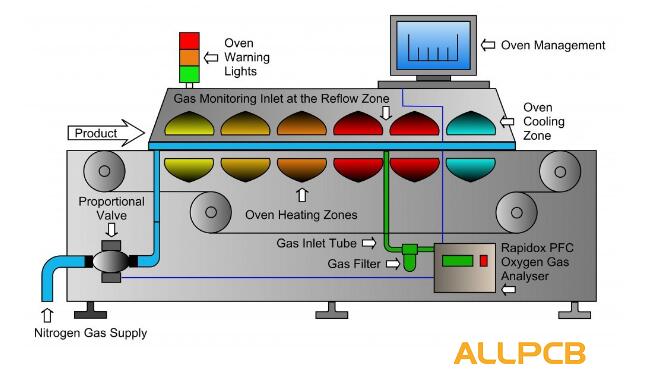

Introduction to reflow soldering method:

Machine type heating method Advantages Disadvantages

Infrared reflow soldering has high thermal conductivity, it can stand with high temperature steepness, also it is easy to control temperature curve, and control the temperature of the upper and lower PCBs during double-sided soldering. And for the shadow effect, uneven temperature, which are easy to cause component or PCB partial burnout.

Hot air reflow soldering Convection conduction temperature uniformity, good welding quality. Temperature gradient is not easy to control.

Forced hot air reflow soldering Infrared hot air hybrid heating Combines the advantages of infrared and hot blast stoves to achieve excellent soldering results when soldering products.

Forced hot air reflow soldering is divided into two types according to its production capacity:

Machine type Application situation Advantages Disadvantages

Large-scale production of temperature zone equipment is suitable for mass production of PCB boards placed on the conveyor belt. It must pass through several fixed temperature zones in sequence, and there will be temperature jump phenomenon when the temperature zone is too small, which is not suitable for high-density assembly board welding. And it is bulky and consumes a lot of power.

Small-scale bench-top equipment in the temperature-free zone is quickly developed in a small space. The temperature changes with time according to the set conditions, and the operation is simple, especially suitable for BGAQFPPLCC. Rework of defective surface mount components (especially large components) is not suitable for mass production.

Due to the characteristics of "reflow" and "self-positioning effect" of the reflow soldering process, the reflow soldering process requires relatively loose mounting accuracy, and it is relatively easy to achieve high automation and high speed of soldering.

At the same time, due to the characteristics of reflow and self-positioning effects, the reflow process has stricter requirements on pad design, component standardization, component tip and printed board quality, solder quality and process parameters.

Cleaning is a process that uses physical and chemical reactions to remove contaminants and impurities from the surface of the object being cleaned. Whether it is solvent cleaning or water cleaning, it must be surface wetted, dissolved, emulsified, and the soil is peeled off from the surface of the surface-assembled board by applying different mechanical forces, and then rinsed or rinsed. Finally blow dry, dry or naturally dry.

Any inappropriate temperature curves can affects product quality, as it can cause soldering defects such as incomplete soldering, soldering, component erection, and excessive solder balls on the PCB.

SMT is a comprehensive system engineering technology that covers substrates, designs, equipment, components, assembly processes, production accessories and management.

SMT equipment and SMT process require stable voltage on the operation site, prevent electromagnetic interference, anti-static, have good lighting and exhaust emission facilities, and have special requirements for operating environment temperature, humidity, air cleanliness, etc. Personnel should also be trained in professional technology.

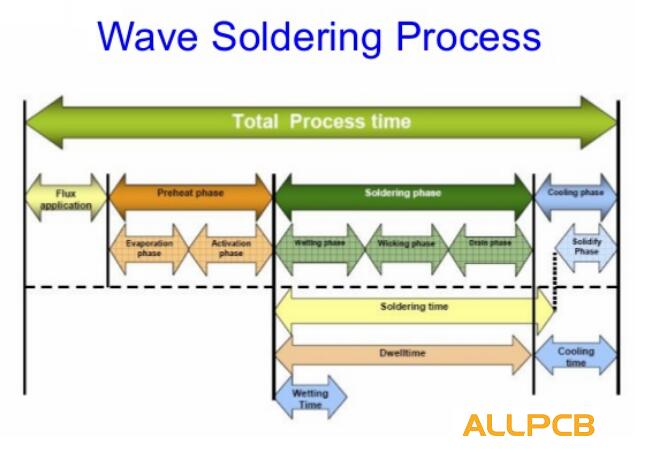

Wave soldering refers to the melting of solder (lead-tin alloy) through an electric pump or electromagnetic pump into a solder peak required by the design, or by injecting nitrogen into the solder pool to pre-load components.

The printed board passes solder peaks to achieve soldering of the mechanical and electrical connections between the soldered ends of the components or between the leads and the printed board pads. Wave soldering systems can be divided into many types depending on the peaks of the different geometries used in the machine.

Wave soldering process: insert the component into the corresponding component hole - pre-coat flux - pre-bake (temperature 90-1000C, length 1-1.2m) - wave soldering (220-2400C) - remove excess plug foot-check.

The reflow is a process of assembly the solder joints with the surface mount components and electrical connections between the leads and the PCB pads by re-Melting the cream solder pre-dispensed onto the PCB pads.

Wave soldering has a new welding process as people become more aware of environmental protection. In the past, tin-lead alloys were used, but lead is a heavy metal that is very harmful to the human body.

So now there is a lead-free process. It uses tin-silver-copper alloy and special flux and the soldering temperature requirements are higher and higher preheating temperature. It is also necessary to set up a cooling zone workstation after the PCB board has passed the soldering area. This aspect is In order to prevent thermal shock; on the other hand, if there is ICT, it will have an impact on the detection.

Wave soldering can be basically solved, it is a little larger than the small component solder, he is different from reflow soldering, and reflow soldering it to the board and components, in fact, is to liquefy the original solder paste In order to achieve the purpose of connecting the components to the board.

Wave soldering work mode: the board enters the machine port - the sensor senses the post-spray FLUX (flux) - the preheating zone begins to preheat - the sprinkler starts to spray Tin-cooling.

Wave soldering: the molten solder forms a peak to solder the component;

Reflow soldering: high temperature hot air forms a reflow to the component soldering.

Reflow soldering has soldered in front of the furnace. In the furnace, only the solder paste is melted to form solder joints.

Wave soldering is soldered in front of the furnace and soldered in the furnace.

Reflow soldering is a solder chip component, wave soldering pin components.

At present, a lot of boards are used for both. Generally, the first patch (no foot, surface mount) is reflowed after reflow (with feet) and then the peak machine.

My Message

My Message

Suggestions

Suggestions