PCB solder mask is one of the important components in the PCB manufacturing process. In-depth understanding of solder mask related knowledge will help engineers design PCBs with better functions and quality. This article will explore the composition of PCB solder mask and the important role it plays.

Composition of PCB solder mask

1. Resin

- Resin is the basic component of PCB solder mask, which determines the basic performance of the ink. Common types of resins include epoxy resin, acrylic resin, polyester resin, etc.

2. Pigment

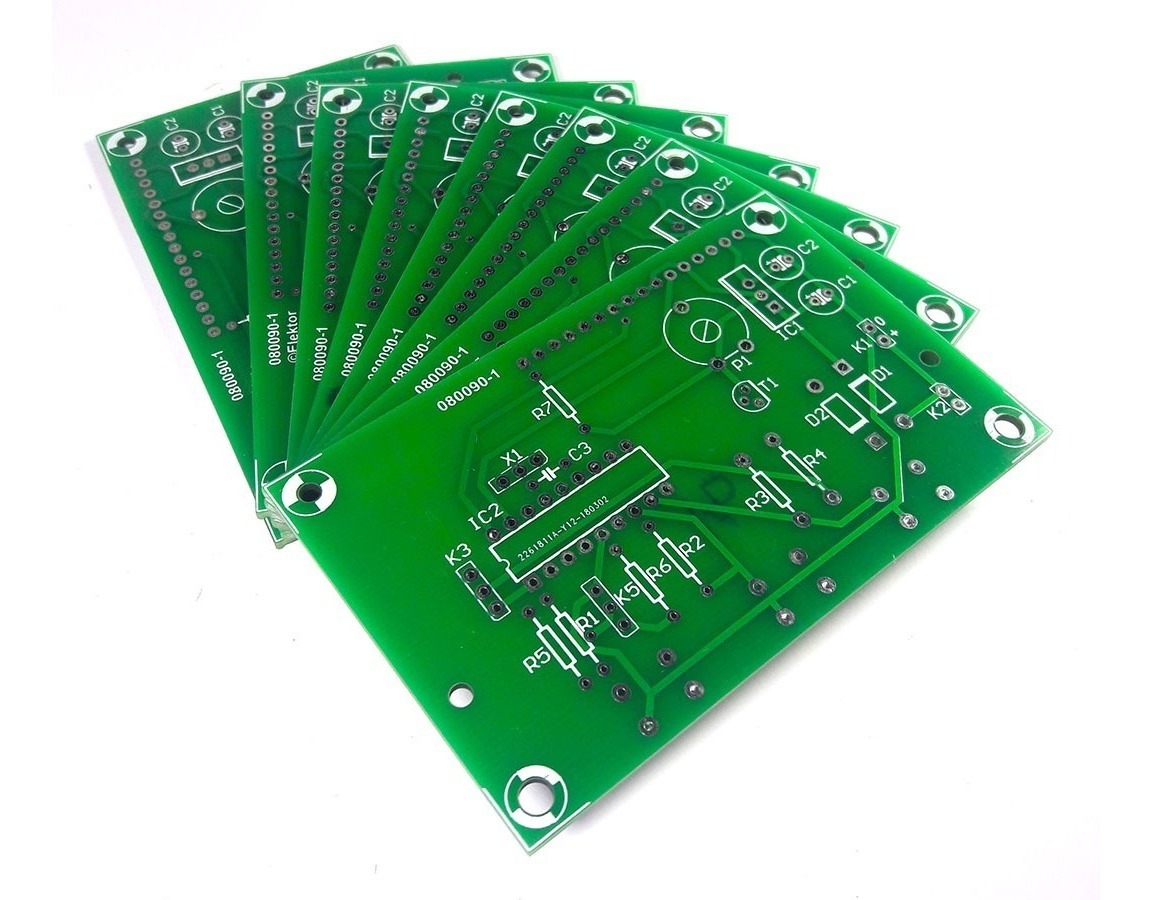

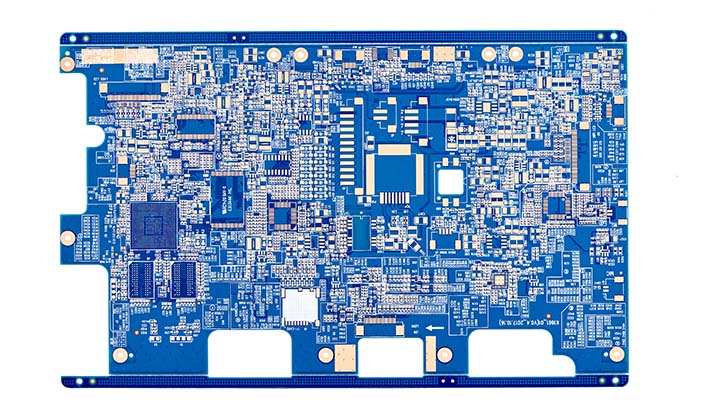

- Pigments give PCB solder mask a specific color. Common colors include green, blue, black, white, etc.

- The choice of pigment not only affects the appearance of the PCB, but also is related to the light reflectivity and thermal stability of the solder mask layer. At the same time, it will also affect the manufacturing cost to a certain extent.

- Green is the most common solder mask color because it is visually comfortable and has a moderate reflection of light, which helps to reduce light interference.

- Green ink can achieve smaller errors, smaller areas, and higher precision. Green, red, and blue have higher design precision than other colors.

-Green ink has better characteristics than other colors. Green has better characteristics than other colors, especially the plugging characteristics of green.

-Green ink is relatively cheaper. Since green is the mainstream in the production process, the process is the most mature and simple, the purchase volume of green ink will naturally be larger, so its purchase cost will be lower than other colors.

-PCB color has no effect on the function of the circuit board.

3. Solvent

- Solvents play a role in adjusting the viscosity and fluidity of PCB solder mask to facilitate the coating and printing of ink.

- The volatility of solvents has an important influence on the drying speed and curing effect of ink.

4. Additives

- In order to improve the performance of PCB solder mask, various additives are usually added, such as defoamers, leveling agents, dryers, ultraviolet absorbers, etc.

PCB solder mask thickness standard

PCB solder mask must have good film forming properties, and its thickness is subject to regulatory requirements. At present, most circuit board manufacturers conduct identification according to the US civil standard IPC-SM-840C specification. In this standard, the solder mask thickness of Class 1 products is unlimited; the minimum solder mask thickness of Class 2 products is 10um; the minimum thickness of Class 3 products should be 18um. The flame retardancy of solder mask is usually based on the specifications of the US UL agency and must pass the requirements of UL94V-0 (UL94-flammability test of plastics for components in devices and equipment).

Generally, the solder mask thickness in the middle of the line is not less than 10um, and the thickness on both sides of the line is not less than 5um.

The functions of solder mask

1. Prevent short circuit and leakage

- The lines on the PCB are dense and the spacing is small. If there is no protection of solder mask, adjacent lines may cause short circuit or leakage due to accidental contact. solder mask covers the area where soldering is not required, forming an insulation barrier, which effectively avoids this situation.

2. Provide insulation protection

- Electronic equipment will be subject to various electromagnetic interference and voltage fluctuations during operation. Good insulation performance is essential to ensure the normal operation of the circuit. PCB solder mask can isolate the circuit from the external environment, prevent moisture, dust, corrosive gases, etc. from entering, thereby improving the insulation resistance and voltage resistance of the PCB, and ensuring the stability and reliability of electronic equipment.

3. Protect the circuit from mechanical damage

- During the manufacturing, assembly and use of PCBs, they will inevitably be subject to various mechanical stresses, such as plugging and unplugging components, collisions during transportation, etc. solder mask can provide a tough protective film for the circuit, reduce the impact of mechanical damage on the circuit, and extend the service life of the PCB.

4. Improve soldering quality

- solder mask clearly defines the soldering area, making the soldering process more accurate and efficient. It can prevent solder from flowing in unnecessary areas, reduce the occurrence of soldering defects such as cold soldering and bridging, and improve the assembly quality and production efficiency of PCBs.

5. Enhance corrosion resistance

- Electronic equipment may be exposed to various corrosive substances such as acids, alkalis, salts, etc. in the use environment. solder mask can prevent these corrosive substances from directly contacting the metal circuits on the surface of the PCB, thereby delaying the corrosion and oxidation of the circuits and improving the corrosion resistance and service life of the PCB.

6. Optimize heat dissipation performance

- Some types of PCB solder mask have certain thermal conductivity, which can help components on the PCB dissipate heat and improve the working stability and reliability of electronic equipment.

7. Beautify the appearance

- In addition to its functional role, PCB solder mask can also provide a beautiful appearance for the PCB. solder masks of different colors and patterns can make the PCB look more neat and professional, and enhance the market competitiveness of the product.

What is the reason for the PCB solder mask to fall off?

1. When the PCB is printed with ink, the pre-treatment is not done well, such as stains, dust or impurities on the surface of the PCB board, or some areas are oxidized. In fact, it is very simple to solve this problem. Just do the pre-treatment again, but strive to clean the stains, impurities or oxide layer on the surface of the circuit board.

2. The baking time of the circuit board is short or the temperature is not enough, because the circuit board must be baked at high temperature after printing the thermosetting ink, and if the baking temperature or time is insufficient, the strength of the ink on the board will be affected.

3. The ink quality problem or the ink is expired, or the ink of an unknown brand is purchased, which will also cause the circuit board ink to fall off when passing through the tin furnace.

As an indispensable part of the PCB manufacturing process, the reasonable matching and performance optimization of the components of PCB solder resist ink are of great significance to ensure the quality and performance of PCB. By preventing short circuits, providing insulation protection, protecting circuits from damage, improving soldering quality, and enhancing corrosion resistance, PCB solder resist ink provides a strong guarantee for the stable operation and long-term reliability of electronic equipment. With the continuous development and innovation of electronic technology, the performance requirements for PCB solder resist ink will continue to increase. I believe that in the future, the technology of solder resist ink will continue to improve and make greater contributions to the development of the electronics industry.