Available for multiple substrates to meet different surface finishing needs.

One-stop tool, prototype, and batch processing service to save your time and cost.

Over 50 certified metal and plastic materials to choose from. Standardized management to ensure reliable quality.

Anodizing

Anodizing Brush

Brush Bead blasted

Bead blasted Polishing

Polishing Laser

Laser Silk Screen

Silk ScreenCNC turning with live tooling combines both lathe and mil capabilities to machine parts with cylindrical features from metal rod stoch.

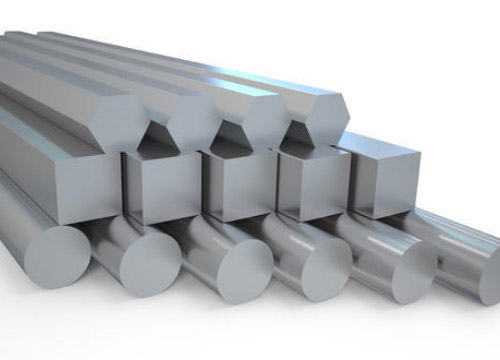

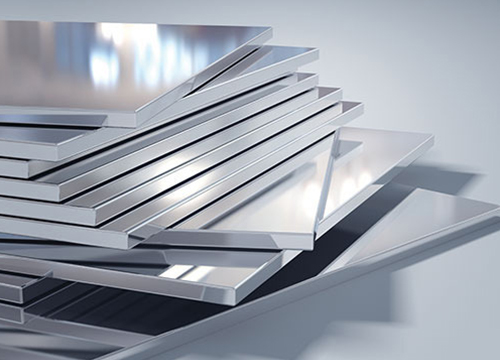

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to rapidly cut solid platic and metal blocks into final parts.

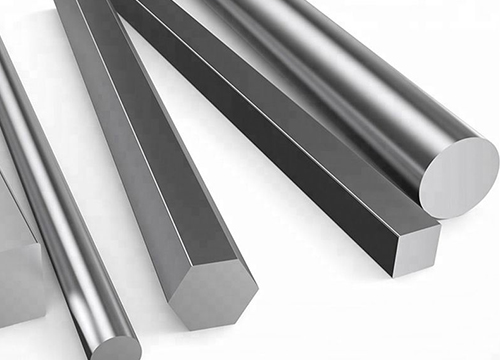

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

Aluminum 6061 has good mechanical properties, exhibits, good weldability, and is very commonly extruded. It is one of the most common alloys of aluminum for general-purpose use.

Mechanical propertiesUltimate tensile strength:291 - 320 MPaElongation at break:12 - 17 %Yield strength:193 - 290 MPaHardness:60 HRBModulus of elasticity:68 - 74 GPa

Aluminum 5052 is a strain hardening aluminum alloy with excellent corrosion resistance. Suitable for marine applications. Can be welded.

Mechanical propertiesUltimate tensile strength:190 - 320 MPa Yield strength:75 - 280 MPa Young's modulus(modulus of elasticity):68 - 71 GPa Elongation at break:2 - 22 % Hardness:46 - 83 HB

Aluminum 7075-T6 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels.

Mechanical propertiesUltimate tensile strength:434 - 580 MPa Yield strength:359 - 530 MPa Young's modulus(modulus of elasticity):69 - 76 GPa Elongation at break:2 - 11 % Hardness:79-86 HRB

ABS (CNC) has good mechanical properties and excellent impact resistance. It is commonly used to prototype parts prior to injection-molding.

Mechanical propertiesUltimate tensile strength:27.6 - 55.2 MPa Yield strength:18.5 - 51 MPa Young's modulus(modulus of elasticity):1.1 - 2.9 GPa Elongation at break:10 - 50 % Hardness:5.6 - 15.3 HV

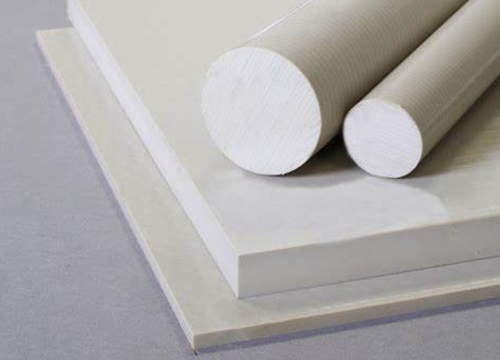

Teflon (CNC) - PTFE - has excellent thermal and chemical resistance and outstanding frictional and electrical properties.

Mechanical propertiesUltimate tensile strength:25 - 31 MPa Yield strength:14 - 41.4 MPa Young's modulus(modulus of elasticity):0.39 - 2.25 GPa Elongation at break:300 - 450 % Hardness:50 - 65 Shore D

POM is the easiest to machine engineering plastic. Ideal for parts with high stiffness, low friction and very low water absorption.

Mechanical propertiesUltimate tensile strength:60 - 89.6 MPa Yield strength:48.6 - 72.4 MPa Young's modulus(modulus of elasticity):2.5 - 4 GPa Elongation at break:15 - 75 % Hardness:14.6 - 24.8 HV

PEEK (CNC) is an engineering thermoplastic with excellent mechanical and thermal properties. Can be used to replace metal parts. Biocompatible.

Ultimate tensile strength:70.3 - 103 MPa Yield strength:87 - 95 MPa Young's modulus(modulus of elasticity):3.76 - 3.95 GPa Elongation at break:30 - 150 % Hardness:26.1 - 28.5 HV

Nylon 6 (CNC) - PA 6 - has excellent mechanical properties, with high toughness and hardness. Susceptible to moisture absorption.

Ultimate tensile strength:64.7 - 79.1 MPa Yield strength:51.2 - 63.8 MPa Young's modulus(modulus of elasticity):1.58 - 1.97 GPa Elongation at break:200-300 % Hardness:16.4-18.1 HV

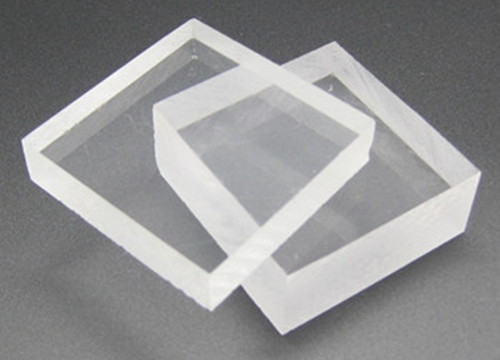

PMMA is a transparent rigid plastic often used as a substitute for glass.

Mechanical propertiesUltimate tensile strength:55 - 83 MPa Yield strength:64 -80 MPa Young's modulus (modulus of elasticity):2.76 - 3.3 GPa Elongation at break:3 - 6.4 % Hardness:64 - 105 HRM

PVC is the third most used plastic with all-around good mechanical properties, excellent chemical and weather resistance and good toughness.

Ultimate tensile strength:46 - 58 MPa Yield strength:53 - 58 MPa Young's modulus(modulus of elasticity):2.18 - 3.41 GPa Elongation at break:25 - 80 % Hardness:13.7 - 16.6 HV

Polycarbonate (CNC) - PC - has excellent impact strength and good temperature resistance. Suitable for outdoor applications. Can be colored or semi-transparent.

Ultimate tensile strength:60 - 72.4 MPa Yield strength:59- 70 MPa Young's modulus(modulus of elasticity):2 - 2.44 GPa Elongation at break:50 - 120 % Hardness:17.7 - 21.7 HV

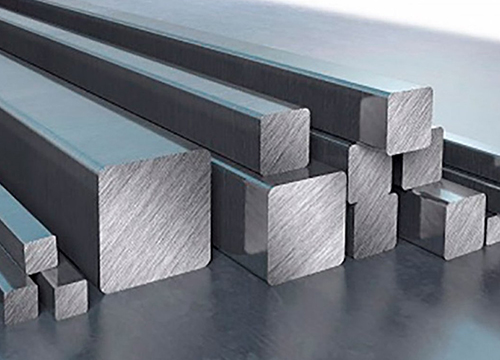

Stainless steel 304L (CNC) has excellent mechanical properties and good machinability. Resistant to most environments and corrosive media.

Mechanical propertiesUltimate tensile strength:480 - 620 MPa Yield strength:190 - 310 MPa Young's modulus(modulus of elasticity):191 - 205 GPa Elongation at break:45 - 60 % Hardness:75-83 HRB

The second most used stainless steel after 304, the general purpose austenitic stainless steel 316 has superior corrosion resistance particularly in chloride containing environments and good elevated temperature strength. The low carbon version 316L has even better corrosion resistance in welded structures.

Mechanical propertiesUltimate tensile strength:480 - 620 MPa Yield strength:170 - 310 MPa Young's modulus(modulus of elasticity):190 - 205 GPa Elongation at break:30 - 50 % Hardness:75 - 83 HRB

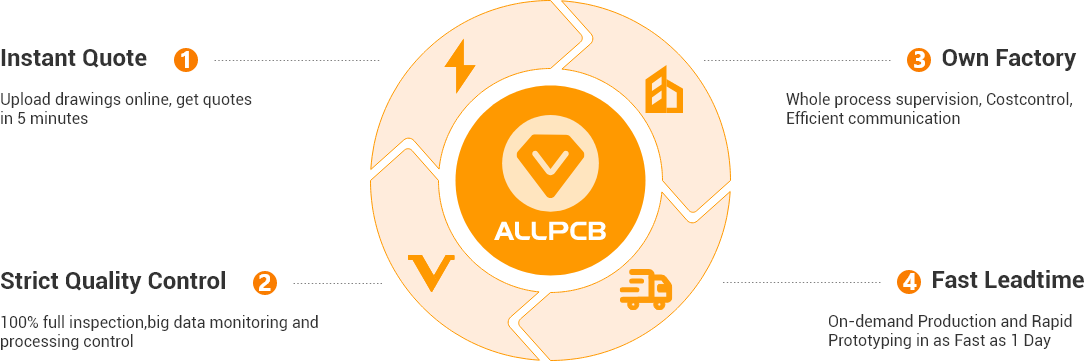

Professional engineer team and service team provide you with one-to-one 360° real-time online service, and regular production feedback reports.

ALLPCB has a powerful IT digital production management system to provide fast, comprehensive and high-quality product processing services.

Upload files to get instant quote or contact customer service for manual quotation.

Select material and finishing requirements, confirm production plan.

Check your order and pay. Add sales to get VIP services.

Blanking - Programming - Processing - Post processing, Inspection - Delivery

Check products with the drawing. We will react to quality problems as soon as possible.