No MOQ request. Even one product can also be printed and produced.

JP2300 is a high-precision photosensitive resin material. It is the most widely used photosensitive resin material.

The part will have a smooth surface, high precision, small shrinkage, water resistance, and chemical resistance. The parts have a certain adsorption force and mechanical properties. It can meet general painting requirements.

JP2300(White)

100mm ±0.1mm

JP2300E photosensitive resin is an ABS-like photosensitive resin with high dimensional accuracy and durability. It is suitable for the production of popular products.

Small shrinkage rate, excellent product dimensional accuracy; fine surface, high resolution; good durability of parts;

Brown / opaque

100mm ±0.1mm

JP3000 is a high-precision photosensitive resin with matte opaque brown color, high precision, clear edges and corners, low shrinkage, and no discoloration.

Excellent precision, clear edges and corners of parts, better in details, low shrinkage rate, and stable size;

Brown / opaque

100mm ±0.1mm

DSM 128 material is a widely-applied low-viscosity photosensitive resin material developed by DSM company. It is similar to engineering plastics ABS and PBT.

Smooth surface, stable dimension, high precision, excellent toughness, waterproof and moisture-proof. It is satisfied with the post-painting, silk-screening, electroplating, and other process requirements.

White

100mm ±0.1mm

JP1300 photosensitive resin can withstand temperatures up to 130℃, which can simulate the thermal properties of engineering plastics. It can be used in high-temperature scenarios such as vacuum plating, water plating, baking paint, and quick molds.

Temperature resistance up to 110-130℃, excellent dimensional stability, high-resolution in details, high strength and sturdiness.

Red / translucent

100mm ±0.1mm

JP1800 is a colorless and transparent material. It is suitable for general use, detailed modeling, and transparent visualization simulations.

The surface of the workpiece is smooth, stable, waterproof, and nearly colorless after the polishing and oil injection process.

Colorless / transparent

100mm ±0.1mm

DSM Taurus is a high-performance photosensitive resin developed by DSM. It can be applied in various prototype verification and final-use parts manufacturing. It can produce large parts with excellent performance.

It has both thermal and mechanical properties, wear-resistant and durable, and has excellent precision for large-size parts;

Black / translucent

100mm ±0.1mm

Hundreds of cutting-edge 3D printers and related equipment can help shorten the product development cycle, reduce product

development costs, and reduce the risk of direct mold opening for customers

3D printing technology is mainly used in industrial design, architectural engineering and construction, 3D metal printing, automotive,

aerospace, equipment manufacturing, medical care, education, cultural creativity, jewelry design, and other fields.Different shapes of parts are generated from

computer graphics data, thereby the development cycles of products are greatly shortened while productivity gets increased and production costs get reduced.

Mechanical and Electrical Industries

Mechanical and Electrical Industries

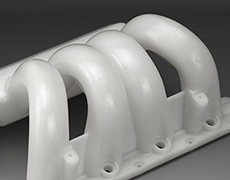

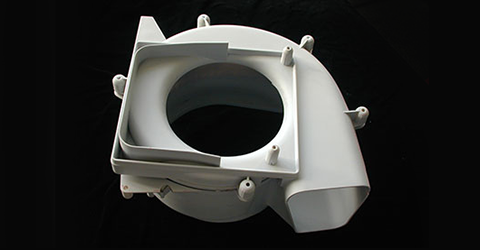

Assembly parts

Assembly parts

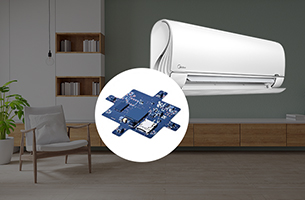

Digital appliances

Digital appliances

Auto parts

Auto parts

Aerospace

Aerospace

Sculpture

Sculpture

Graduation works

Graduation works

Medical Industry

Medical Industry