PCB Fabrication + Component Sourcing + Assembly + Testing – All in One Place

ISO 9001, IPC-A-610 Class 2/3 Standards, 100% AOI & X-Ray Testing

DFM/DFA Analysis, BOM Optimization, and Design Guidance

Access to 1000+ suppliers, BOM optimization, and risk mitigation

SMT, THT and Mixed assembled technology

Single/Double sided assembly

Lead-free (RoHS compliant)

Low-Temperature Soldering for Flex PCBs

Box Build Assembly

01005 chip size

0.3mm BGA spacing

0.25mm fine-pitch ICs

Automotive-Grade Components (AEC-Q Certified)

Turnkey, Consigned, Partial Turnkey

Rigid, Flex PCB, Rigid-Flex PCB

HDI with Blind/Buried Vias (Up to 32 Layers)

Ceramic/Metal-Core Substrates

RF/Microwave PCBs (±5% Impedance Control)

20+ SMT Lines (Prototype to Mass Production)

Daily Capacity: 10M SMT Joints, 180K DIP Joints, 50+ Designs

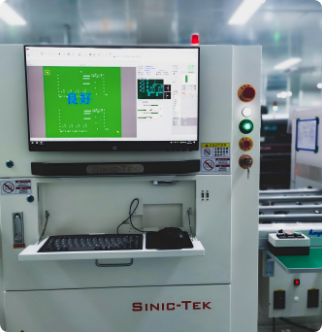

High-Precision Siemens SMT, GKG-G5 SPI, EAGLE 3D AOI

AI-Driven Dynamic Production Scheduling

MES System for Real-Time Yield Monitoring

Partnerships with 1.000+ verified suppliers (Original manufacturers and authorized distributors)

Exclusive Channels for Critical Components (e.g., Automotive MCUs)

Real-Time Market Risk Mitigation

Professional BOM optimization including alternates, lifecycle alerts, and cost-down suggestions

Reduce BOM costs by 15-30% through cross-industry bulk purchasing

MOQ optimization reduces excess inventory by 40%

24-Hour BOM Review & Component Matching

Intelligent Alternate Part Recommendations (>99% Compatibility)

Emergency Order Service (72-Hour Global Delivery)

Smart Warehouse (300K+ SKUs, Humidity/ESD Controlled)

JIT(Just in time) Inventory for Cost Reduction

Safety Stock Alerts for Critical Components

Free DFM/DFA Analysis and 24H customer support

Live dashboard: Real-time yield rate (≥99.2%) & station alerts

IC Programming, Functional Testing

Flying Probe/fixture testing

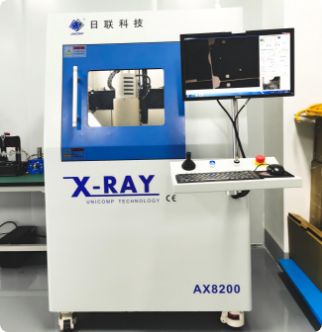

IQC, SPI, Online AOI, Offline AOI, IPQC, X-Ray

IC programming, functional test

Monthly Quality Reports (CPK ≥1.67)

6 Sigma Process Optimization

Full-Process SPC Data Transparency

ISO 9001/14001/45001/13485, IATF 16949, UL Certified

IPC-A-610 Class 2/3 Standards

Customized QCP (Quality Control Plan)

24-Hour Prototyping (1–50pcs)

Small Batch (<500pcs) in 3 Days

Mass Production (Daily 10M+ Joints)

In-House Logistics, DHL/FedEx, DDP

Smart Customs Clearance (<2 Hours)

PCB-PCBA <300m distance: Panel→assembly in 4hr

Real-Time Tracking

Live system monitoring ensures 98% on-time delivery rate

Contingency Plans for Extreme Scenarios

Response within 2 hours

Provide solutions within 2 days

Monthly report and improve

From online quote system or emails, response quickly

Via Email, Skype/Whatsapp or phone

DFM check, BOM optimization, and design guidance

Global component network, Full-process system monitoring

20+ Siemens high precision SMT machines, first sample test

X-Ray testing, functional test and final inspection

Shield bag packaging, DHL/FEDEX/UPS shipping

The professional support team responds complaints within 2 hours and provides immediate solutions

How ALLPCB assembly factory process and what kind of benefits for our customers

Design Review & DFM Analysis

Design Review & DFM Analysis

- Engineers validate PCB design files (Gerber, BOM, CPL) against manufacturing capabilities.

- Perform Design for Manufacturability (DFM) checks for component spacing, pad sizes, and thermal management.

- Risk Mitigation: Prevents costly redesigns by flagging layout errors (e.g., solder bridges, insufficient clearances).

- Cost Optimization:Recommends design tweaks to reduce material waste and improve yield rates.

- Compliance: Ensures adherence to IPC standards (e.g., IPC-A-610) for industry-grade quality.

Component Procurement & Verification

Component Procurement & Verification

- Source components from certified suppliers using real-time inventory databases.

- Authenticate parts via batch-code tracing, X-ray inspection, or third-party lab testing.

- Genuine Parts Guarantee: Eliminates counterfeit risks with supplier audits and COC (Certificate of Conformance).

- Supply Chain Resilience: Multi-sourcing strategies prevent delays for obsolete or long-lead-time components.

- Cost Transparency: Price-match commitments and bulk-order discounts.

Solder Paste Printing

Solder Paste Printing

- Use a stencil and precision printer to evenly coat solder paste on PCB pads.

- Adjust printing parameters (pressure, speed) to ensure solder paste thickness and coverage accuracy.

- The basis of welding quality: accurate solder paste quantity reduces defects such as cold solder joints or bridging.

- Process stability: parameter standardization ensures consistency in batch production.

Solder Paste Inspection (SPI)

Solder Paste Inspection (SPI)

- Detect solder paste thickness, volume and position deviation through 3D optical scanning.

- Real-time feedback data to calibrate printer parameters.

- Defect prevention: intercept solder paste anomalies before soldering to avoid subsequent rework.

- Process control: digital monitoring improves process capability (CPK).

SMT Assembly

SMT Assembly

- Apply solder paste via stencil printing.

- Place components using high-precision pick-and-place machines.

- Reflow soldering in controlled-temperature ovens.

- Precision: ±0.025mm placement accuracy for 0201 packages and micro-BGAs.

- Process Control: Solder paste inspection (SPI) and AOI (Automated Optical Inspection) ensure defect rates <0.1%.

- Traceability: Barcode tracking for every PCB panel.

Reflow Soldering

Reflow Soldering

- The temperature curve is set according to the characteristics of the solder paste, divided into three stages: preheating, reflow, and cooling.

- Precisely control the peak temperature (usually 220–250°C) to form reliable solder joints.

- Welding reliability: avoid cold welding or overheating to ensure the stability of electrical connections.

- Consistency: Temperature curve monitoring ensures uniform soldering quality for each batch.

First sample testing

First sample testing

- Perform electrical tests (such as ICT) and basic functional verification on the first sample.

- Compare with design specifications and confirm key parameters (voltage, signal integrity).

- Early risk exposure: Discover design or process problems in the early stages of production.

- Fast iteration: Reduce rectification costs after mass production.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI)

- Detect solder joint quality, component offset or polarity errors through multi-angle cameras.

- Machine learning algorithms automatically classify defects (such as missing parts and tombstones).

- Comprehensive inspection: Covers more than 99% of visible defects and reduces manual omissions.

- Quality dataization: Generates inspection reports to support continuous process optimization.

Through-Hole Component Soldering

Through-Hole Component Soldering

- Insert leads into drilled holes manually or via automated insertion machines.

- Wave soldering or selective soldering for robust connections.

- Durability: Mechanical strength testing for high-stress applications (e.g., automotive, industrial).

- Consistency: Automated systems eliminate human error in pin alignment.

X-Ray Inspection

X-Ray Inspection

- Use X-ray fluoroscopy to detect hidden solder joints (such as BGA, QFN).

- Analyze whether the solder joint bubble rate and filling integrity meet IPC standards.

- Non-destructive testing: Ensure the internal quality of invisible solder joints.

- High-precision analysis: Quantify defect indicators (such as bubble rate <25%) to ensure long-term reliability.

Testing & Functional Validation

Testing & Functional Validation

- Perform environmental testing (high and low temperature, vibration), aging testing and full functional verification.

- Simulate terminal usage scenarios to ensure stable operation of the product in actual applications.

- Performance compliance: 100% meets customer specifications.

- Durability assurance: Verify product life cycle through accelerated life testing.

Final Inspection & Packaging

Final Inspection & Packaging

- Visual inspection under magnification for cosmetic flaws.

- Anti-static ESD packaging with moisture barrier bags.

- Labeling and serialization for logistics tracking.

- Aesthetic Standards: Reject boards with scratches, discoloration, or misalignment.

- Shipping Safety: MIL-STD-2073-compliant packaging to prevent transit damage.

- Delivery Tracking: Real-time logistics updates via integrated courier APIs.