Integrated Order Customized Production and Processing services

ALLPCB intelligent manufacturing provides personalized production and processing customization services

With the rapid integration of traditional industries and the Internet, the manufacturing industry has undergone great changes, gradually transforming from the original large-scale assembly line production to small-batch and multi-variety customized production.Standardization is being replaced by customization. We ushered in a new era of industrial production. In the era of showing individuality, people are pursuing unconventional things: want a Hello Kitty pink air conditioner, want to design a set of unique clothes in the world, want to customize an exclusive washing machine through the Internet... these sounds some funny and even absurd requirements have now become reality.

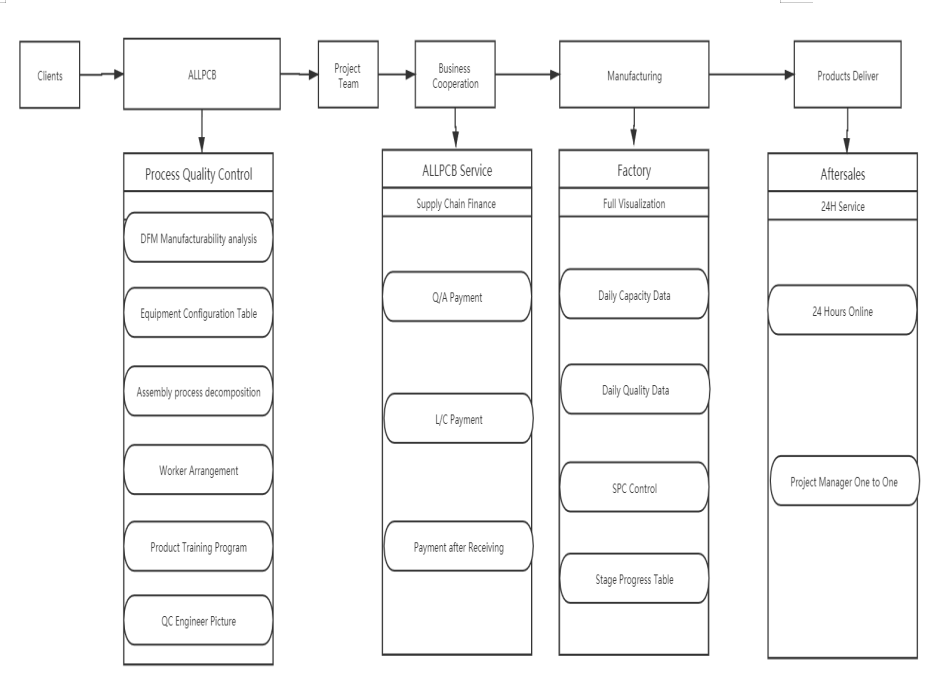

Customer needs come first, and companies place orders for production according to customer needs. This is customization. But customization also has its difficulties. Its difficulty is also the core issue in the customization process, which is how to effectively import client demand data into the enterprise and how to effectively affect the enterprise's production and manufacturing. Since each customer’s style, needs, hobbies, etc. are different and different from person to person, customization is unique and it is not easy to carry out mass production, which greatly extends the delivery time. Affect customer satisfaction. The road to a large-scale personalized customized smart factory is an overall smart solution practice including smart design, smart manufacturing, and smart sales. To solve this problem, in the process of product customization and processing, two points should be clarified: First, all data related to product manufacturing is open for customers to consult at will; Second, customers can participate in the entire process of manufacturing and have strong interaction The information exchange channels are transparent and effective communication.

ALLPCB Intelligent Manufacturing Factory is composed of large-scale personalized customization platform construction, digital production workshop construction, and information system (ERP, MES, WMS, SCADA, etc.) construction. The whole process applies big data and Internet of Things technologies to carry out independent design, The system automatically schedules production, which completely subverts the traditional methods of manual plate making and manual production scheduling in the traditional manufacturing industry, and realizes the digitization of the entire process from order placement to factory end order, production scheduling, and dispatching production, creating a new industrial Internet-based Demonstration factory for personalized customization of the platform.

From the Internet to big data, to mass customization and finally to mass customization production. Extending from manufacturing to service, while grasping more consumer demand, is the focus of the transformation and upgrading of the manufacturing industry. The Internet era has brought opportunities to the development of manufacturing, but it should not be limited to Internet thinking. The Internet does not replace us, but supports us to go better and farther.

ALLPCB Intelligent Manufacturing is a few smart factory in the world that provides one-stop small batch and multi-variety personalized production and processing customization services.

It only takes one step to meet personalized production and processing services, and we will leave the rest to us.

Special team members

The members of the project team involve multiple fields, medical devices,

Equipment configuration

SMT personalized collocation, according to the degree of difficulty of the customer's products, and the automatic line configuration for the annual procurement requirements, to ensure the special line production

Operator management

Product quality control management

Online visual management

24-hour online service

Supply chain financial services

【Disclaimer】

1, ALLPCB releases the news to disseminate more information. It doesn’t represent the viewpoint of ALLPCB!

2, ALLPCB doesn’t guarantee the accuracy, authenticity, integrity, validity, timeliness and originality of the information (including but not limited to words, data and icons)!

3, ALLPCB doesn’t verify the relevant information, which cannot be taken into your consideration of investment. Or else at your own risk!

4, For any infringement, please contact the author directly, or write emails to ALLPCB to get the feedback!