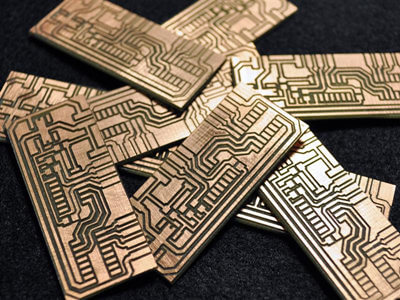

Attentions in PCB Copper Cladding

Copper cladding is an essential part of PCB design. Copper cladding is to take the unused space on the PCB board as a reference and fill with solid copper, which aims to enhance the anti-resistance capacity, improve the power efficiency and reduce the loop area.

PCB Copper Cladding

And here are some attentions to achieve the expected result of copper cladding:

1. If there are several grounds like SGND, AGND and GND, it is necessary to conduct different treatment according to the position. Besides, it is better to bold the power connection relatively, to form a plurality of multi-deformable in different shape.

2. For the single point connection of different grounds, the best option is to connect by 0 ohm resistor, inductor or magnetic beads.

3. The cladding copper around crystal oscillator is to take the crystal oscillator as the high frequency emission source and then clad the copper around crystal oscillator that separately grounded.

4. At the beginning of layout, grounding should be given equal attentions. It is better to make an excellent layout instead of relying on vias to eliminate the ground pin, which is a good choice for PCB manufacture.

5. No sharp corner should be allowed on PCB board. From the perspective of electromagnetic, a corner on PCB board means a transmitting antenna that will influence the circuit in the future. So you’d better to apply rounding edge.

6. Do not clad copper on the spare layout area of multilayer for the difficulty in good ground of the cladding copper.

7. To achieve the good grounding about the inner metal, like metal radiator and metal reinforcement, etc.

8. The radiation metal of three-terminal voltage regulator must be well grounded. And the grounding isolation zone must be well grounded.

In short, if the ground of cladding copper on PCB is well treated, it definitely brings more good than harm. It can reduce the reflux area of signal line and reduce external electromagnetic interference for signal.