How to make a reasonable thermal design?

Thermal design is to take appropriate measures and methods to reduce the components temperature and PCB board temperature, in order to make the system work at the proper temperature. This article will mainly discuss the thermal design from the aspects of reducing the heat of components and PCB board, and speeding up the thermal dissipation.

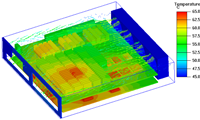

Thermal Design

There are three main sources of heat in the PCB: (1) the heat of electronic components; (2) the heat of PCB board itself; (3) the heat of the rest parts. Among them, the components heat is the main heat source, followed by the heat generated by the PCB circuit board.

1) The heat of components is determined by its power consumption, so small power components should be the first choice to minimize heat.

2) Separate the temperature-sensitive components and high heat source. Around heating device there should be enough space left for thermal dissipation gas to flow. Heating components should be separated arranged. The components of high thermal performance should be installed in the downwind, and the components of low thermal performance should be installed in the upwind.

3) The cooling device such as the radiator or heat pipe can be added on PCB board to cool the electronic components. When the temperature cannot come down, a radiator with a fan can be used to enhance the cooling effect.

4) As the heat generated by the components will pass to PCB board, so it’s important to increase the cooling capacity of PCB board, so as to distribute the heat out through the PCB board. Use PCB board with high thermal dissipation performance. Usually the PCB board is made of epoxy glass fabric plate, and the small amount of heat can be distributed through the components and itself.

5) Make reasonable layout thermal design. The resin has poor thermal conductivity, copper foil circuit and holes are good conductor of heat, so to improve copper foil residual rate and increase the thermal hole is the main means of cooling. The thicker the copper foil is, the higher the residual rate of copper foil is; the more layers there are, the greater the equivalent thermal conductivity is, and the better the cooling effect of PCB board is. Therefore, when designing the PCB layout to improve the cooling capacity, thick circuit, thick copper foil, multi-layer, large area of copper, more thermal holes should be taken into account.