● Manual soldering

● Dip soldering

● Wave soldering

● Selective soldering

Instant Quote

Full feature prototype PCB custom service at low cost.

Flexible PCB

Customized FPC service with high standards

Rigid-Flex PCB

High precision rigid-flex PCB customized service

PCB Assembly Quote

Leading assembly factory with Siemens production line

SMD-Stencil

Laser cutting high precision stencil service

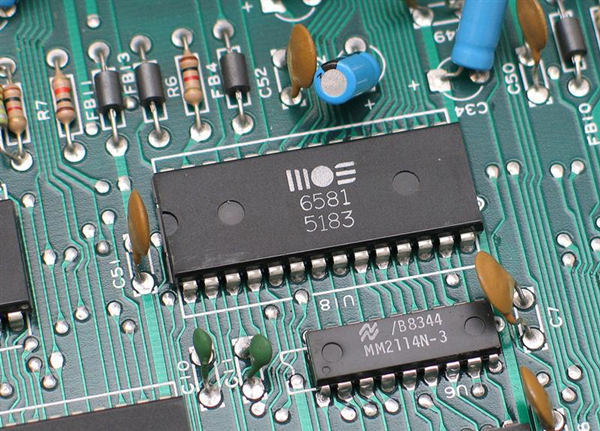

Through-hole technology almost completely replaced earlier electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology (SMT) became popular in the late 1980s, every component on a typical PCB was a through-hole component.

Through-hole Soldering

Here are several typical through-hole soldering method:

Manual Soldering

Manual soldering is suitable for very small run production. Welding quality depends on the operators’ experience and skills. And it can be improved through training courses and standards.

Dip soldering

With this soldering method, the operators need to be close to hot solder pot and flux smoke. Thus, this method is more difficult to do and it is dangerous for the operators.

Advantage: low cost of per solder joints, fast soldering speed.

Wave Soldering

Wave soldering is the most common and effective way. The system of wave soldering has a big enough wave soldering tin that is able to handle the maximum expected board width. Wave soldering is usually applied in medium-volume or large-volume PCB soldering.

Selective Soldering

Selective soldering is a special soldering method. When some components have been installed on PCB board, wave soldering is unable to be used for installation of through-hole components so that selective soldering becomes the only way to solder through-hole components on the board.