● Through-hole Components

● Point-to-point Construction

Instant Quote

Full feature prototype PCB custom service at low cost.

Flexible PCB

Customized FPC service with high standards

Rigid-Flex PCB

High precision rigid-flex PCB customized service

PCB Assembly Quote

Leading assembly factory with Siemens production line

SMD-Stencil

Laser cutting high precision stencil service

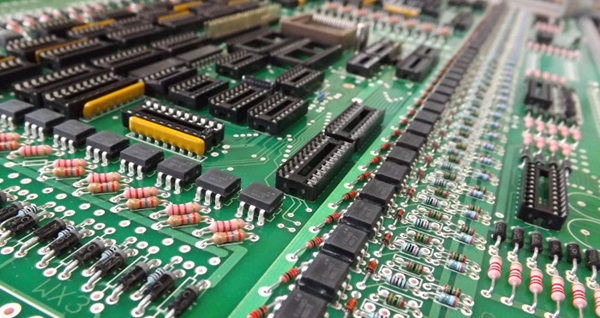

Through-hole technology refers to the mounting electronic components, which involves the use of leads on the components that are inserted into holes drilled in printed circuit board (PCB) and soldered to pads on the opposite side either by manual assembly or by the use of automatic insertion mount machines.

Through-hole Technology

A variety of through-hole parts with two leads, like resistors, capacitors, and diodes, is done by bending the leads 90 degrees in the same direction, inserting the part in the board, soldering the leads and trimming off the ends. Leads may be soldered either manually or by a wave soldering machine.

Through-hole technology almost completely takes the place of earlier electronics assembly techniques such as point-to-point construction. Before surface mount technology became popular in the late 1980s, every component on a typical PCB was a through-hole component.

However, through-hole technology increase the cost by requiring many holes to be drilled accurately, and limits the available routing area for signal traces on layers immediately below the top layer on multi-layer boards since the holes must pass through all layers to the opposite side.